When considering boat wrap installation, choose between 3M and Avery Vinyl based on needs: 3M for durability & UV protection, Avery for customization & brand visibility. Meticulous surface preparation, including cleaning, sanding, and priming, is crucial. Professional installation ensures a seamless, protective finish that enhances aesthetics and guards against environmental damage, using tools to avoid imperfections.

“Elevate your boat’s aesthetics and protection with the ultimate upgrade: professional boat wrap installation using 3M or Avery vinyl. This comprehensive guide delves into the world of marine wraps, offering an in-depth look at the materials, preparation process, and step-by-step application for a seamless finish. Whether you’re a seasoned boater or new to the scene, understanding the intricacies of boat wrap installation is key to achieving a high-quality, long-lasting transformation.”

- Understanding Boat Wrap Materials: 3M vs Avery Vinyl

- Preparation and Surface Readiness for Wrap Installation

- Step-by-Step Guide to Professional Boat Wrap Application

Understanding Boat Wrap Materials: 3M vs Avery Vinyl

When considering a boat wrap installation, understanding the materials is paramount. Two prominent brands in the industry are 3M and Avery Vinyl, each offering distinct advantages for vehicle enhancement. 3M, renowned for its high-performance adhesives and protective coatings, provides wraps with superior durability and UV resistance. These wraps are ideal for those seeking long-lasting protection against environmental factors and the wear and tear of daily use.

On the other hand, Avery Vinyl offers a range of vibrant colors and custom graphics options, making it an excellent choice for those looking to personalize their boats or enhance their brand visibility on the water. Their wraps are known for their ease of application and ability to provide a smooth, professional finish. Custom vehicle wraps from either brand can transform a boat into a mobile marketing tool, allowing owners to showcase their creativity and style while increasing visibility during boat wrap installation.

Preparation and Surface Readiness for Wrap Installation

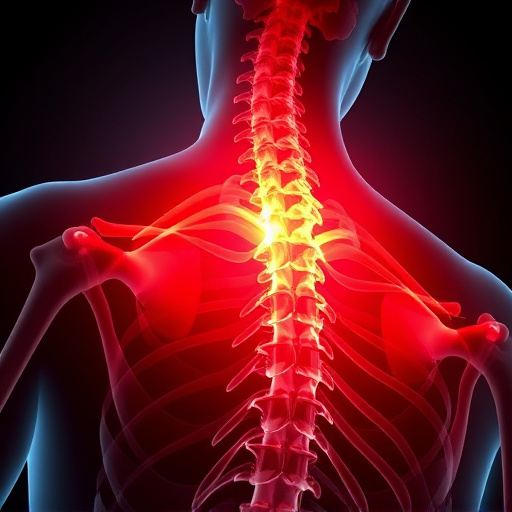

Before embarking on a boat wrap installation with high-quality materials like 3M or Avery vinyl, ensuring the surface readiness is paramount. The preparation process begins by thoroughly cleaning and inspecting the boat’s exterior to remove any dirt, debris, or existing protective films such as paint protection film (PPF) or window tinting. This meticulous step guarantees a clean canvas for the new wrap, enhancing its adhesion and longevity.

A smooth and dry surface is essential for optimal boat wrap installation. Addressing any imperfections like scratches or rough spots through sanding and filling ensures a seamless fit for the vinyl wrap. Additionally, applying a suitable primer can significantly improve the bond strength between the wrap and the boat’s surface, offering long-lasting protection against the elements.

Step-by-Step Guide to Professional Boat Wrap Application

A professional boat wrap application is an art that transforms your vessel’s exterior, offering both aesthetic enhancement and protection. The process involves several meticulous steps to ensure a flawless finish. It starts with thorough preparation, including a detailed paint correction to create a smooth surface for the wrap. This initial stage is crucial as it ensures the adhesive bond between the vinyl and the boat’s gel coat or paint is strong and long-lasting.

Once the surface is ready, designers lay out the custom graphics (if applicable) carefully, aligning them precisely with the boat’s curves. The high-quality 3M or Avery vinyl is then meticulously unrolled and applied, section by section, following the contours of the hull. This requires skill to avoid bubbles, creases, or overlaps, ensuring a seamless, professional finish. Expert installers use premium automotive services tools and techniques to achieve this, guaranteeing a top-notch final product that not only boosts the boat’s visual appeal but also protects its surface from the elements.

Boat wrap installation using high-quality 3M or Avery vinyl is a professional way to transform your vessel’s appearance. By understanding the materials, preparing the surface thoroughly, and following a step-by-step guide, you can achieve a sleek, durable finish that enhances your boat’s aesthetic appeal. This process not only adds value but also provides protection against the elements, ensuring your boat looks its best for years to come.